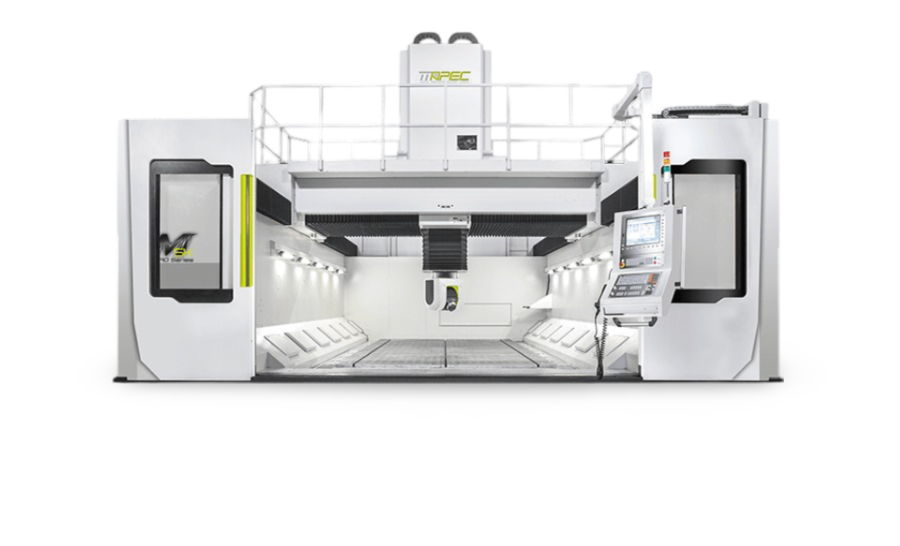

Introducing APEC, a proud subsidiary of TTGroup, at the forefront of advanced cnc gantry machines for aerospace manufacturing. Apec specializes in medium and large aerospace structure and engine parts processing. With our partnership with APEC, we bring together the best of both worlds to offer our clients unparalleled access to top-tier technology and innovation. Phillips Machine Tools in partnership with APEC can propel your aerospace manufacturing processes to new heights with innovative solutions and technical expertise.

Configuration-

Box-in-Box structure Symmetrical geometry design with Box-in-Box structure of cross beam and saddle. Excellent force flow design decreases thermal deformation. High accuracy during high-speed machining can be performed.

Unequal thickness of Ram with honeycomb structure Ram equipped with honeycomb structure performs the best balancing design and better geometry.

Crossbeam flushing system A high-pressure pump with groups of powerful nozzles can quickly remove the chips.

Complex chip removal system A dual-chip removal system with a large-capacity water tank could make coolant and chip removal stable.

5-axis simultaneous machining 5-axis machining accuracy difference is below 0.01mm.

Special spindle for aluminum alloy processing Ultra-high-speed and power spindle with the best material removal rate.

X/Y/Z-axis driven by linear motor All three axes are driven by dual linear motors. Max. feedrate:60 m/min Max. acceleration:5 m/sec²

Automatic attachment head exchange system Different angle heads could be mounted to match various applications and it is best for machining in narrow spaces.

Automatic top-roof cover Movable beam design of top-roof cover could prevent the spreading of chips and coolant liquid.